| Sign In | Join Free | My xpandrally.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xpandrally.com |

|

Brand Name : TANKII

Model Number : NICR Alloy

Certification : ISO9001

Place of Origin : Shanghai, China

MOQ : 100 KG

Price : negotiable

Payment Terms : L/C, T/T, Western Union

Supply Ability : 100 Tons per month

Delivery Time : 7-20 days

Packaging Details : Spool + Carton + Wooned Case

Model NO. : NICR 9010 8020 6015

Process Method : Stranded Nichrome Wire

Leads : 7/19/37

Trademark : TANKII

HS Code : 75052200

Production Capacity : 3000tons/Years

Surface : Bright surface

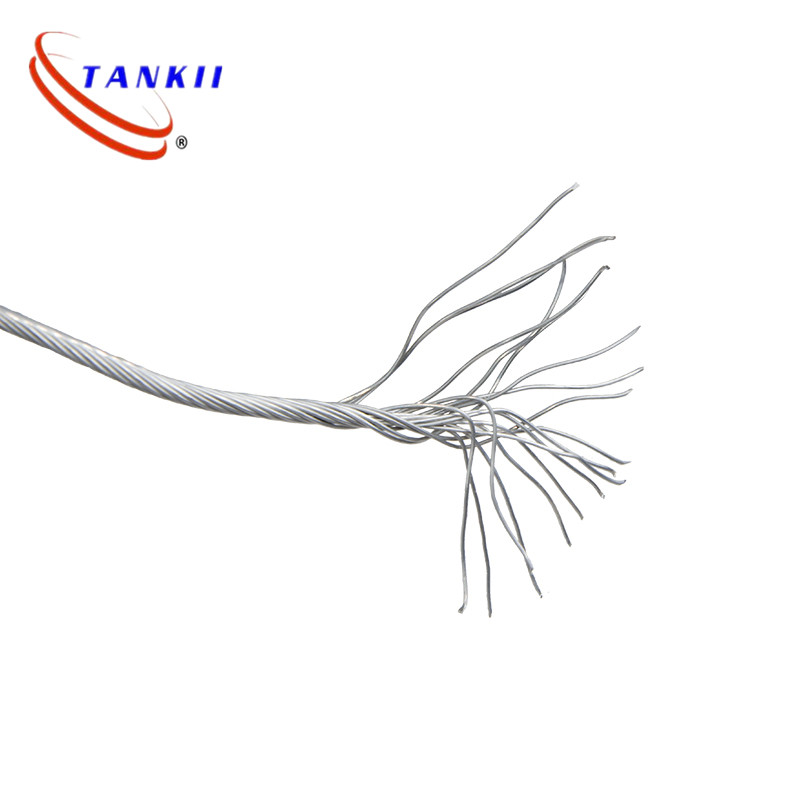

NiCr 60/15 80/20 90/10 8020 Nichrome 19X0.574 18×0.523+1×0.574 Pure Nickel Chrome Stranded Wire for Electric Heater

Stranded resistance wire is made of Nichrome alloys, such as Nichrome 80/20,Nichrome 60/16, etc.

Stranded nichrome wire can be made with 7 strands, 19 strands, or 37 strands, or other configurations.

Stranded resistance heating wire has many advantages, such as deformation ability, thermal stability, mechanical character, shockproof ability in thermal state and anti-oxidization.

Nichrome Wire forms a protective layer of chromium oxide when it is heated for the first time.

Nichrome wire beneath the layer will not oxidize, preventing the wire from breaking or burning out.

Due to Nichrome Wire's relatively high resistivity and resistance to oxidation at high temperatures, it is widely used in heating elements, electric furnace heating and heat-treating processes in the chemical, mechanical, metallurgical and defense industries,

| Nickel Grade | Ni+Co | Cu | Si | Mn | C | Cr | S | Fe | Mg |

| ≥ | ≤ | ||||||||

| Ni201 | Bal. | .25 | .3 | .35 | .02 | .2 | .01 | .3 | - |

| Ni200 | Bal. | .25 | .3 | .35 | .15 | .2 | .01 | .3 | - |

| Alloy | Standard Strand Construction, mm | Resistance,Ω/m | Strand Diameter Nominal, mm | Meter per Kilo |

| NiCr 80/20 | 18×0.544+1x0.574 | 0.252-0.278 | 2.67 | 26 |

| NiCr 80/20 | 19×0.61 | 0.205-0.250 | 3.05 | |

| NiCr 80/20 | 18×0.523+1x0.574 | 0.271-0.299 | 2.67 | 30 |

| NiCr 80/20 | 19×0.574 | 0.227-0.251 | 2.87 | 25 |

| NiCr 80/20 | 36×0.385+1x0.45 | 0.265-0.293 | 2.76 | 26 |

| NiCr 60/15 | 19×0.508 | 0.286-0.318 | 2.54 | |

| NiCr 60/15 | 18×0.523+1x0.574 | 0.276-0.305 | 2.76 | 30 |

| Ni200/Ni201 | 19×0.574 | 0.019-0.021 | 2.87 | 21 |

| N6 | Chromel C, Ni 60, N6, HAI-NiCr 60, Tophet C, Resistohm 60, Cronifer II, |

| Electroloy, Nichrome, Alloy C, Ni 6, MWS-675, Stablohm 675 | |

| N7 | Ni 70, Chromel 70/30, N7, Hytemco, HAI-NiCr 70, Balco, Tophet 30, |

| Resistohm 70, Cronix 70, Stablohm 710 | |

| N8 | Chromel A, Ni 80, N8, Nichrome V, HAI-NiCr 80, Tophet A, Resistohm |

| 80, Cronix 80, Protoloy, Ni 8, Alloy A, MWS-650, Stablohm 650 |

| Propertes/Grade | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Main Chemical composition | Ni | Rest | Rest | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Rest | Rest | Rest | |

| Max. continuous service temp. of element | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Resistivity at 20oC (μ Ω · m) | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Density (g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Thermal conductivity(KJ/m· h· oC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of lines expansion(α × 10-6/oC) | 18 | 17 | 17 | 19 | 19 | |

| Melting point (approx. )( oC) | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Elongation at rupture (%) | > 20 | > 20 | > 20 | > 20 | > 20 | |

| Micrographic structure | austenite | austenite | austenite | austenite | austenite | |

| Magnetic properties | nonmagnetic | nonmagnetic | nonmagnetic | nonmagnetic | nonmagnetic | |

|

|

NiCr 60/15 80/20 90/10 8020 Nichrome 19X0.574 18×0.523+1×0.574 Pure Nickel Chrome Stranded Wire for Electric Heater Images |